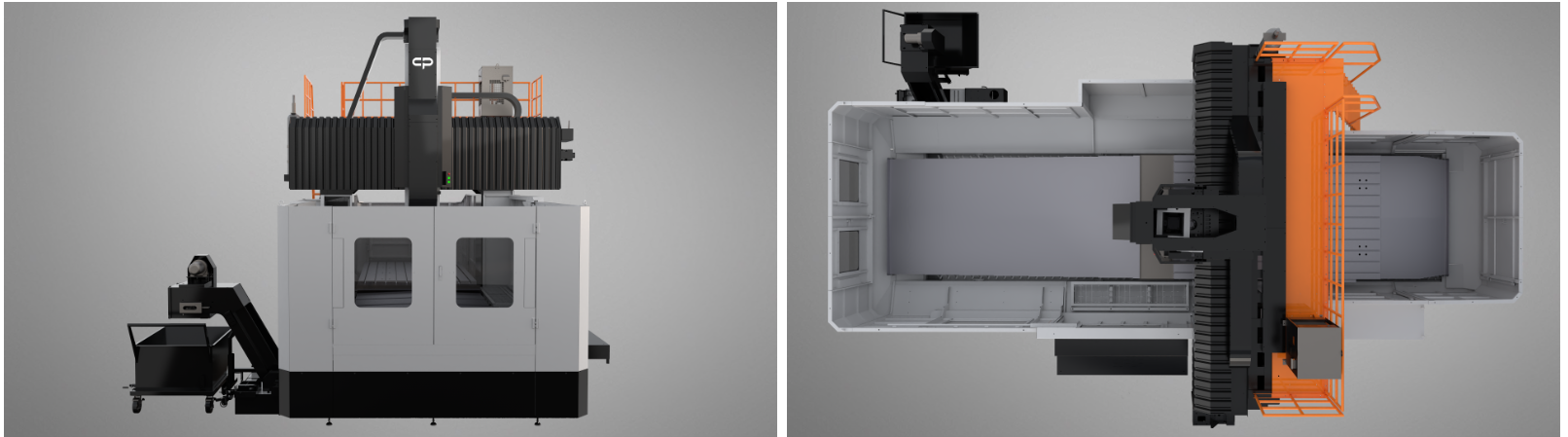

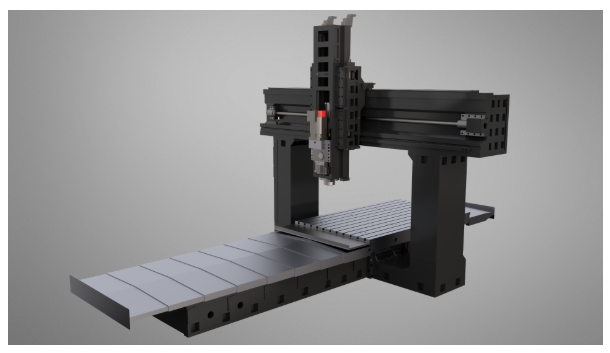

& ZOPO II superior series T-type slide adopts advanced gantry design concept, combined with FEA finite element analysis, which effectively reduces the deformation of machine during processing, while improving processing accuracy and precision retention.

& The full range of modular designs provides customers with more configuration options.

& The product types are rich and the series are complete to meet the processing needs of different industries; it is suitable for various materials such as aluminum alloy, cast iron, steel, etc.

& The overall external protection design is ergonomic, user-friendly, easy to operate and maintain, and has a good waterproof and anti-chip optimization design effect.

All castings are made of high-strength gray cast iron with vibration absorption ability, and are aged to ensure stability. The reinforcing ribs are well designed to have excellent bending resistance to ensure the stability of the machine.

& Ram:The double balance bars are symmetrically distributed on both sides to improve the precision of the moving parts of the ram.

& Worktable:The worktable is hollowed out, the T-slot spacing on the table is 200mm, and the moving parts are lightweight, which improves the responsiveness of the machine during dynamic processes.

& Machine body:The one-piece casting body and the larger span of the body rails effectively enhance the load-bearing capacity of the worktable.

& Beam:The guideways on the crossbeam and saddle joint surfaces are distributed vertically and orthogonally to improve the overall rigidity and precision stability of the machine.

& Two column distance:The full range of two column distance and Y travel are designed to maximize the range of machine, and can be freely equipped with a variety of accessory milling heads; effectively improving the processing capacity of the machine.

Relying on the in-depth collaboration between ZOPO software development engineers and CNC system companies, we continuously carry out secondary development based on standard CNC systems to create multi-functional and intelligent human-machine interfaces, creating a more efficient and convenient user experience for customers.

& Energy-efficient processing mode selection

& Tool management function

& Broken blade detection function

& Troubleshooting guide function

& Super strong human-computer interaction interface

More details, pls contact

Lammy Zhang

E-mail: lammyzhang@163.com, info@qdtopmac.com

Mobile: 0086 137 8060 8796

E-mail: lammyzhang@163.com

Skype: lammy-zhang

What'sapp: +86 13780608796

Wechat: 13780608796

QQ: 94438220